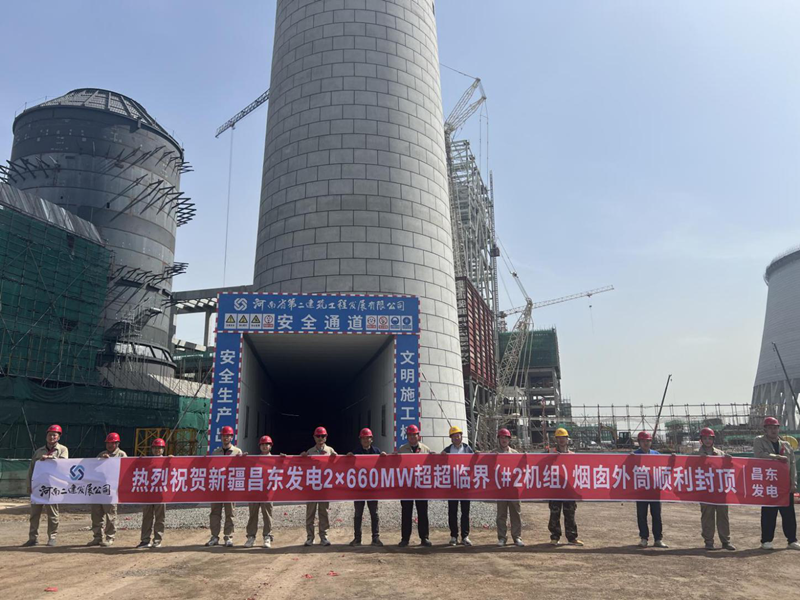

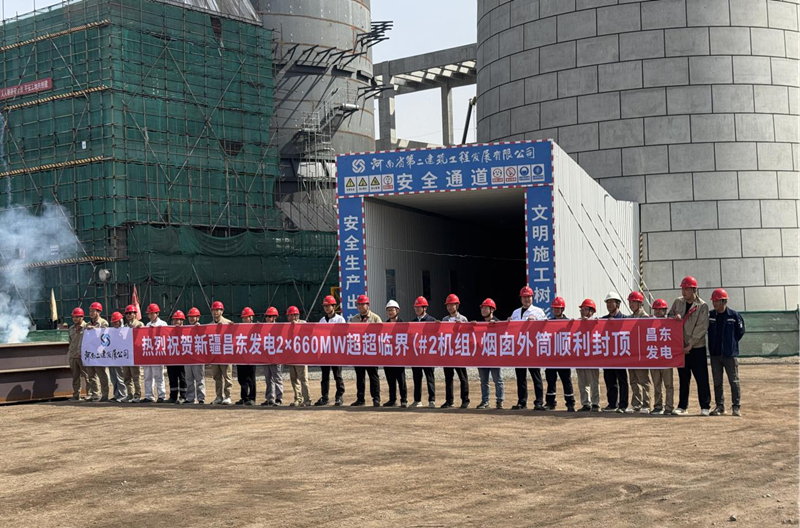

At 10:58 a.m. on June 4, 2025, with the completion of the last cubic meter of concrete pouring, the outer cylinder of the chimney of the 2×660MW ultra-supercritical (Unit #2) of Xinjiang Changdong Power Generation, which was constructed by our company, was successfully capped. This marks a major breakthrough in the key node of the project and lays a solid foundation for the subsequent construction and overall commissioning.

Overcome difficulties and create benchmark projects

As one of the core facilities of the 2×660MW ultra-supercritical (Unit #2) project of Xinjiang Changdong Power Generation, the chimney has an outer cylinder height of 204 meters. During the construction process, with the strong support of the company's leadership and neighboring projects, the project team worked together with one heart and overcame challenges such as hot summers, cold winters, strong winds, and sandstorms. By optimizing the construction plan and adhering to the principles of "advanced planning, process control, one-time excellence, and quality first", we always prioritize construction safety and quality, strictly implement all safety measures, and implement a hierarchical acceptance system. We focus on controlling key quality control points and procedures to ensure that the safety and quality of chimney construction are always under control. And it has been highly recognized by the owner and the supervision unit.

Multi-party collaboration highlights the spirit of craftsmanship

At this topping-out ceremony, Guo Qifeng, the general manager of the new energy sector of Xinjiang Qiya Group, the construction unit, Li Gentao, the project manager, Luo Haidong, the project director of the supervision unit, and the project members of the construction unit witnessed this significant moment together. Guo Qifeng, the general manager of Qiya, stated: "The successful capping of the chimney is the result of the collaboration of your company's team. We hope to continue to carry forward your company's spirit of 'setting a Qiya benchmark and creating a model project', ensure the smooth completion of subsequent inner cylinder installation and other procedures, and guarantee the timely commissioning of the chimney system."

Looking to the future, we strive for the full completion

The chimney topping out sounded the clarion call for the decisive victory of the project. In the next step, our project department will continue to be guided by the company's enterprise spirit, constantly carry forward the company's fine traditions, establish the company's image, and create high-quality projects in the industry.