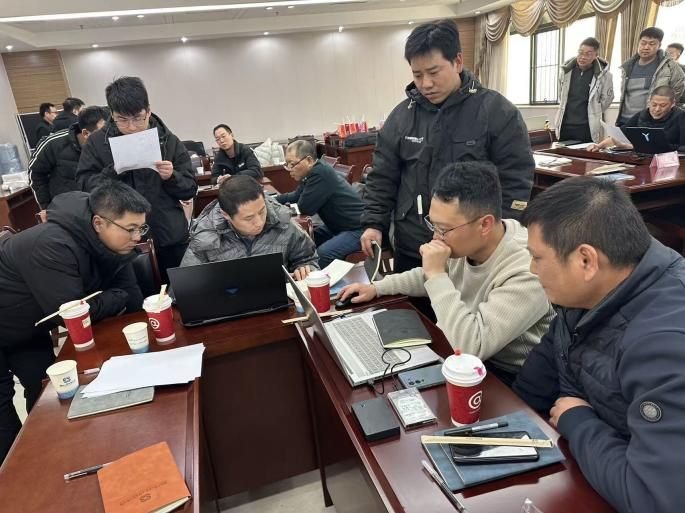

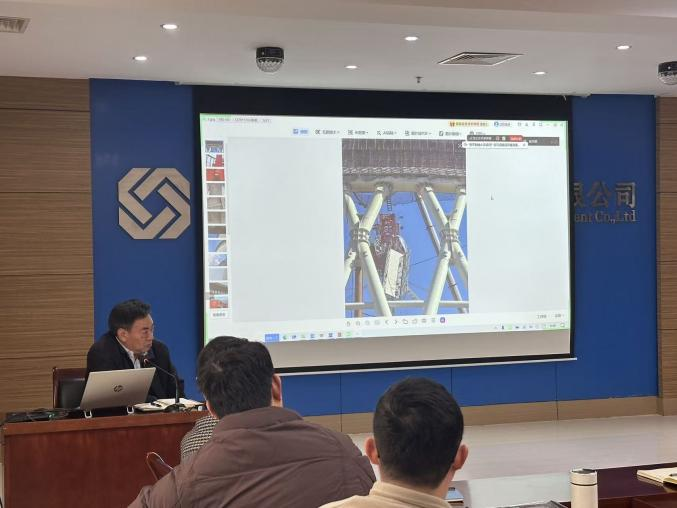

To comprehensively enhance the company's quality and technical management level and promote internal technical exchanges, the Quality and Technology Center organized an annual quality and technology system meeting on December 18–19, 2025. Over 80 participants, including chief engineers, technical staff, and quality inspectors from various projects, attended the meeting either in person or online. The meeting was conducted in a seminar format. It began with a presentation by Engineer Zhao Yupeng from the Liaocheng Xiangguo Power Plant Phase II Project, who explained key aspects of high-support formwork construction. Subsequently, participants broke into groups to discuss specific case studies, with each group’s representative presenting their problem-solving approaches. This interactive format significantly improved overall engagement and deepened understanding of the topics, stimulating enthusiasm among attendees while also helping personnel across different projects rapidly strengthen their professional expertise. The meeting specially invited Engineer Zhang Yunlong from Pinming Company to provide on-site Q&A support. Addressing common challenges encountered in daily use of Pinming’s safety calculation software, Mr. Zhang offered precise solutions and delivered an in-depth explanation of techniques and key considerations for efficiently optimizing construction plans using the software, thereby providing strong technical support for on-site operations. Each group engaged in intense discussions. Regarding guidance on excellence creation initiatives, Li Youpeng from the Engineering Management Department and Gao Linpo, the technical lead responsible for the national-level quality project application at the Jiaozuo East Waste-to-Energy Power Plant, delivered detailed presentations on the requirements for national quality engineering awards, scoring criteria, key points for on-site re-inspection, and precautions during inspection visits. Their sessions helped participants deeply understand the award’s core philosophy of "pursuing excellence and creating timeless classics," reinforcing their determination to learn from best practices and strive for excellence. Subsequently, Li Na, head of the Engineering Management Department, summarized the quality and technical work of 2025: First, systematically promoting and implementing newly issued management regulations; second, conducting in-depth analysis of common quality and technical issues encountered during the year, urging project teams to draw broader lessons from specific cases and enhance technical awareness; third, setting forth expectations for further improving quality and technical management, recommending the use of the PDCA (Plan-Do-Check-Act) cycle to clarify priorities and drive continuous improvement in construction quality. Additionally, Kong Deshan, Deputy Chief Engineer of the company, shared insights based on his personal experience, presenting challenging construction scenarios and classic case studies. He emphasized how technology can ensure quality, reduce costs, and improve efficiency, and offered practical suggestions drawn from years of field expertise. He urged all attendees to pay close attention to construction details, noting that complacency often arises in seemingly simple tasks, which can lead to significant safety hazards. Zhao Yupeng delivered a presentation on high-support formwork engineering Zhang Yunlong provided an explanation of Pinming software Li Youpeng explained the evaluation criteria and procedures for the National Quality Project Award Each group presented their problem-solving approaches General Engineer Kong shared his construction experience Director Li summarized the quality and technical work Finally, the meeting emphasized that quality and technical work must be carried out with a commitment to excellence and the principles of comprehensive quality management, requiring continuous learning and improvement. All participants are encouraged to strengthen their professional competence through rigorous work ethics, fulfill their responsibilities diligently, continuously advance in their respective roles, and grow together with the company. Submitted by the Engineering Management Department