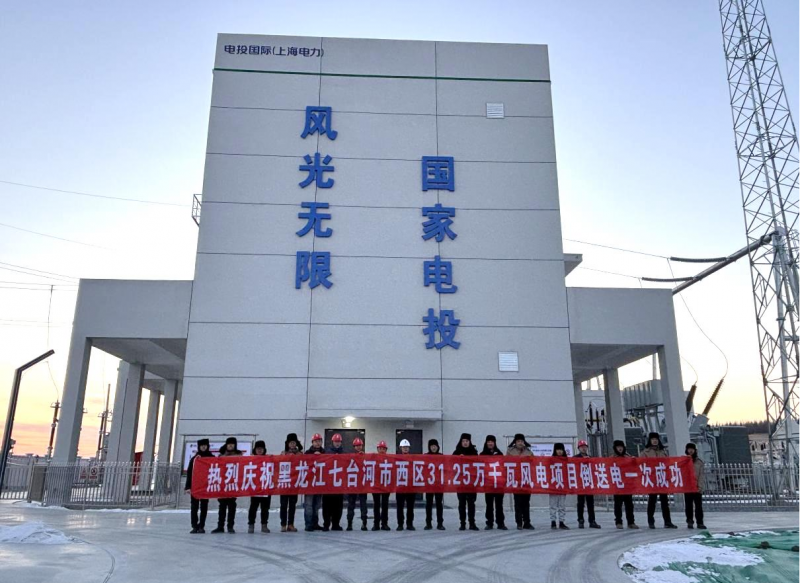

The final wind turbine installation and substation back-feeding of the Heilongjiang Qitaihe Wind Power Project were both successfully completed, marking a dual milestone in the project's construction progress. At 15:17 on December 22, 2025, the final blade was precisely connected to the nacelle hub, marking the successful completion of the last wind turbine installation using the Jinli luffing tower crane. Simultaneously, the 220-kilovolt substation achieved successful reverse energization in one attempt. This milestone signifies a critical breakthrough in the project, officially establishing the key "power transmission" pathway and ushering the project into the final phase of system commissioning and grid connection. These achievements lay a solid foundation for realizing full-capacity grid integration. The project is located in Xinxing District and Boli County of Qitaihe City, Heilongjiang Province. As a key initiative to promote energy structure optimization and support green, low-carbon transformation, it has a total installed capacity of 312.5 megawatts, comprising 50 hybrid-tower wind turbines each with a capacity of 6.25 MW (hub height at 160 meters). It also includes the construction of a 220-kilovolt booster substation and a collector power line system. During construction, the project team confronted multiple challenges including complex terrain, extreme weather conditions, and the transportation of oversized components. Through scientific evaluation of lifting plans, optimized construction scheduling, enhanced meteorological monitoring, and round-the-clock site management, the team efficiently completed the installation of all wind turbines. To date, eight turbine units have already completed grid connection testing, while the remaining units are progressing steadily with electrical installation and system commissioning. This reverse energization process served as a comprehensive test of the installation quality of equipment and the effectiveness of system commissioning at the booster substation. With close coordination between equipment manufacturers and installation and commissioning teams, all equipment operated stably and monitoring data remained within normal ranges, successfully enabling power from the external grid to be smoothly fed back into the substation. This achievement provides stable voltage support for subsequent wind turbine power generation and grid connection, demonstrating the high level of management expertise and technical capability inherent in modern renewable energy projects. Harnessing the wind of innovation and riding the momentum of the times, the project team is taking concrete actions to respond to the nation’s “dual carbon” strategy. Committed to advancing green and low-carbon development, the team will seize the successful completion of the substation reverse energization and turbine installation as a key opportunity. Upholding quality as the fundamental principle, they will fully advance subsequent grid connection commissioning, trial operations, and full-capacity commissioning efforts. The team strives to achieve comprehensive project operation at the earliest possible date, injecting strong "green momentum" intoHeilongjiang Qitaihe Xiqu 312.5 MW Wind Power ProjectSubmitted by

Strictly Uphold the Assessment Standard, Build a Solid Foundation for Development— 2025 New Employee Business Knowledge ExaminationTo comprehensively evaluate the learning outcomes and job suitability of new employees hired in 2025, the company successfully organized the New Employee Business Knowledge Examination on December 19. Through assessment-based evaluation and motivation, this examination reinforces the talent foundation for the company’s high-quality development.The assessment was conducted through a dual-track model combining offline and online formats, coordinated and deployed by the company's Human Resources Center. A total of 30 examination venues were arranged, bringing together over 190 new employees to take the test simultaneously.At each sub-venue, members of the project department’s leadership teams provided full-process supervision, strictly enforcing examination discipline and following established procedures to ensure that the assessment was carried out in an orderly, rigorous, fair, and transparent manner.The assessment content closely aligned with actual job requirements, covering multiple areas such as engineering fundamentals, project cost estimation, safety standards, material procurement, and financial accounting. It aimed to evaluate the effectiveness of new employees' training and strengthen their competence and readiness for their respective roles.In the examination halls, candidates remained calm, thought carefully, and answered diligently, fully demonstrating the new employees’ solid learning attitude and positive, motivated spirit.This assessment serves not only as a comprehensive review of the new employees’ learning outcomes, but also as a concrete implementation of the company’s talent development philosophy of “using assessments to promote performance.” The results will serve as a key basis for the probation-to-regular evaluation of new employees who joined after graduating in 2025, as well as a standardized professional assessment for those hired through social recruitment. In this way, the examination truly functions as a guiding “baton” in talent evaluation and development.The assessment is not an end, but a brand-new beginning. We look forward to each of you diligently growing in your respective roles—measuring responsibility amidst steel and concrete, accumulating experience through technical challenges, and embodying professionalism and composure in every action. May you transform what you have learned into real job competence, and make your own contribution to the company’s high-quality development!Contributed by the General Office

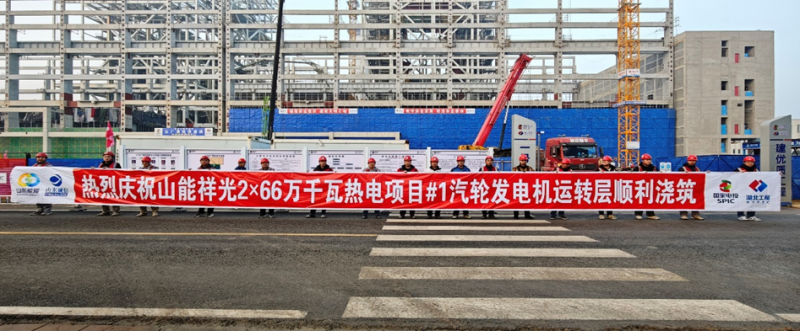

Shandong Energy Liaocheng Xiangguang 2×660 MW Cogeneration ProjectLarge-Volume Concrete Pouring for 1 Turbine Generator Level Successfully CompletedAt 21:17 on December 15, 2025, exciting news came from the construction site of the Shandong Energy Liaocheng Xiangguang 2×660 MW cogeneration project — the concrete pouring for the #1 turbine generator level commenced successfully three days ahead of the scheduled milestone. As the first batch of concrete was slowly poured into the formwork, cheers and applause erupted across the site. The smooth progress of this complex and critical construction phase embodies the dedication and professionalism of all personnel involved. Through round-the-clock efforts, they have solidly laid the "foundation of the power plant’s heart," vividly demonstrating the project team’s resilience, commitment, and ability to overcome challenges and deliver results.As a major people’s livelihood project for energy supply security in the Liaocheng Yanggu area, Unit #1 is scheduled to meet commissioning conditions by the end of October next year, providing reliable heating sources for surrounding residents. The turbine generator base operating level serves as the core load-bearing structure for the unit — the largest in scale, most complex in procedures, and highest in precision across the entire site. It is also the primary and prerequisite condition for unit installation, making it a task with tight deadlines, heavy responsibilities, and significant political and social importance.Faced with a challenging construction environment and technical demands requiring millimeter-level accuracy, the project team rose to the challenge with determination and resolve. On one hand, they scientifically coordinated construction planning, introduced incentive bonuses, implemented a 24-hour two-shift work system, and provided supportive logistical measures such as warm nighttime meals to fully empower frontline workers. On the other hand, they strictly adhered to a “zero-error” construction standard, rigorously controlling the three critical gates—process, specialty, and acceptance—exercising meticulous, full-process management over hundreds of embedded parts, anchor plates, bolts, and sleeves. They strengthened coordination among EPC contractors, supervisors, and owners, conducting layered inspections and approvals by axis, section, phase, and discipline. The company chairman and leaders at all levels have given high priority to the project, visiting the site multiple times to provide guidance and strategic support, injecting strong momentum into the project’s successful advancement.Through the collective dedication and unity of all construction teams, the project successfully achieved the major milestone of completing the turbine generator base operating level — ahead of schedule and passing acceptance with full compliance. This milestone breakthrough has created essential conditions for the subsequent installation of core equipment such as the steam turbine generator sets.Going forward, the project team will uphold the corporate spirit of "unity and perseverance, innovation and excellence, continuous self-strengthening, and steady progress." They will remain vigilant on quality, fortify safety protocols, and fully advance critical upcoming milestones, including the construction of the 14-meter-level large platform in the main powerhouse and the enclosure and waterproofing of the main plant roof trusses.As a key livelihood project in Shandong Province, the steady progress of the Xiangguang cogeneration project will provide strong support for optimizing local energy structures and enhancing heating supply security for residents. The project team, driven by unwavering determination, is poised to write a new chapter in the ongoing success of this vital undertaking.Submitted by the Shandong Energy Liaocheng Xiangguang 2×660 MW Cogeneration Project

To comprehensively enhance the company's quality and technical management level and promote internal technical exchanges, the Quality and Technology Center organized an annual quality and technology system meeting on December 18–19, 2025. Over 80 participants, including chief engineers, technical staff, and quality inspectors from various projects, attended the meeting either in person or online.The meeting was conducted in a seminar format. It began with a presentation by Engineer Zhao Yupeng from the Liaocheng Xiangguo Power Plant Phase II Project, who explained key aspects of high-support formwork construction. Subsequently, participants broke into groups to discuss specific case studies, with each group’s representative presenting their problem-solving approaches. This interactive format significantly improved overall engagement and deepened understanding of the topics, stimulating enthusiasm among attendees while also helping personnel across different projects rapidly strengthen their professional expertise.The meeting specially invited Engineer Zhang Yunlong from Pinming Company to provide on-site Q&A support. Addressing common challenges encountered in daily use of Pinming’s safety calculation software, Mr. Zhang offered precise solutions and delivered an in-depth explanation of techniques and key considerations for efficiently optimizing construction plans using the software, thereby providing strong technical support for on-site operations.Each group engaged in intense discussions. Regarding guidance on excellence creation initiatives, Li Youpeng from the Engineering Management Department and Gao Linpo, the technical lead responsible for the national-level quality project application at the Jiaozuo East Waste-to-Energy Power Plant, delivered detailed presentations on the requirements for national quality engineering awards, scoring criteria, key points for on-site re-inspection, and precautions during inspection visits. Their sessions helped participants deeply understand the award’s core philosophy of "pursuing excellence and creating timeless classics," reinforcing their determination to learn from best practices and strive for excellence.Subsequently, Li Na, head of the Engineering Management Department, summarized the quality and technical work of 2025: First, systematically promoting and implementing newly issued management regulations; second, conducting in-depth analysis of common quality and technical issues encountered during the year, urging project teams to draw broader lessons from specific cases and enhance technical awareness; third, setting forth expectations for further improving quality and technical management, recommending the use of the PDCA (Plan-Do-Check-Act) cycle to clarify priorities and drive continuous improvement in construction quality.Additionally, Kong Deshan, Deputy Chief Engineer of the company, shared insights based on his personal experience, presenting challenging construction scenarios and classic case studies. He emphasized how technology can ensure quality, reduce costs, and improve efficiency, and offered practical suggestions drawn from years of field expertise. He urged all attendees to pay close attention to construction details, noting that complacency often arises in seemingly simple tasks, which can lead to significant safety hazards.Zhao Yupeng delivered a presentation on high-support formwork engineeringZhang Yunlong provided an explanation of Pinming softwareLi Youpeng explained the evaluation criteria and procedures for the National Quality Project AwardEach group presented their problem-solving approachesGeneral Engineer Kong shared his construction experienceDirector Li summarized the quality and technical workFinally, the meeting emphasized that quality and technical work must be carried out with a commitment to excellence and the principles of comprehensive quality management, requiring continuous learning and improvement. All participants are encouraged to strengthen their professional competence through rigorous work ethics, fulfill their responsibilities diligently, continuously advance in their respective roles, and grow together with the company.Submitted by the Engineering Management Department

Good snow promises a bountiful year, and joyful news keeps coming. Following the successful completion of the #2 turbine generator operating floor slab pouring, another milestone was achieved at the Shandong Energy Liaocheng Xiangguang 2×660 MW thermal power project—on December 14 at 10:59 AM, concrete pouring for the lower ring beam of the #2 natural draft cooling tower commenced smoothly, one day ahead of the original schedule.The successful implementation of this pour marks a significant phase breakthrough in the main structure construction of the #2 cooling tower, highlighting the project team’s strong capability in efficient and focused problem-solving. It also lays a solid foundation for the subsequent construction of the cooling tower shaft.As the "heart" of the unit’s heat dissipation system, the construction quality of the #2 natural draft cooling tower directly impacts the future stable operation of the power generation units. Among its key structural processes, the pouring of the lower ring beam is particularly critical—demanding extremely high precision and continuous concreting operations.However, nature posed a challenge: on December 12, a heavy snowstorm suddenly hit the project site, severely disrupting the scheduled inspection activities planned for December 13.“Snow stops, work starts—under no circumstances will we let the snow slow us down!”In response, the project team immediately activated its emergency plan for rainy and snowy weather. Workers swiftly mobilized upon command, voluntarily giving up rest time and rushing to the site fully equipped for safety.The scene turned into a bustling hub of activity: a combined “mechanical + manual” approach was deployed. Crews armed with brooms and shovels conducted a thorough, “carpet-style” cleanup across the inspection zones. Industrial salt was spread on key pathways to prevent icing and slipping. Safety officers remained on-site throughout, meticulously inspecting scaffolding, edge protections, and other critical areas to ensure that safety standards were upheld without compromise—proving that progress and safety go hand in hand, even in harsh conditions.After the snow removal was completed, the project team immediately launched self-inspection activities, conducting a comprehensive and rigorous review of key construction processes—such as the accuracy of rebar installation, the strength of formwork support systems, and the stability of the lower ring beam scaffolding structure.Subsequently, the acceptance inspection team—comprised of representatives from the owner supervision unit, and general contractor—arrived on site to conduct formal verification. Through on-site inspections and data validation, the team confirmed that the construction quality of the lower ring beam fully met the design requirements and relevant industry standards. The inspection was successfully passed, marking official approval for the next phase.At 10:59 AM on the 14th, concrete pouring officially commenced amidst biting cold winds. To address the challenges of winter construction, the project team had made thorough preparations in advance—coordinating with the commercial concrete plant to ensure sufficient supply of concrete mixed with early-strength antifreeze admixtures, guaranteeing that the concrete would meet the required formwork temperature upon placement.The team adopted a well-defined construction method: “pouring initiated at one point and progressed symmetrically around the circumference,” ensuring structural integrity. Dedicated personnel were assigned to monitor critical processes—including concrete placing, vibration, and curing—throughout the operation.On site, managers, construction crews, and technical staff performed their respective duties with seamless coordination, creating a scene of intense yet orderly progress.“Wind and snow temper our original aspirations demonstrates our responsibility!”This achievement—reaching the milestone ahead of schedule—is a testament to the dedication and perseverance of every builder involved.As a key people’s livelihood project in Shandong Province, each step forward in the Xiangguang Cogeneration Project strengthens energy security and winter heating supply for the Liaocheng region.Moving forward, the team will transform the momentum forged in adversity into driving force for construction. Through meticulous execution of every process, they are adding bricks and tiles to the city’s “warmth bill” for residents and its long-term “energy blueprint”—ensuring that the heat of engineering progress truly reaches thousands of households.Contributed by:Shandong Energy Liaocheng Xiangguang 2×660 MW Thermal Power Cogeneration Project Team

The Materials and Equipment Management and Procurement System Conference was successfully held on November 21, 2025, with the aim of further improving the company's materials and equipment management, standardizing management processes, and achieving the core objectives of enhancing quality and efficiency while reducing costs. Over 40 project-level materials and equipment management personnel attended the meeting through both online and offline formats.System Training Strengthens Management FoundationIn his opening remarks, Li Huitao, Director of the Materials and Equipment Center, expressed sincere appreciation for the hard work and dedication of all materials management staff. He emphasized that the company is currently in a period of rapid development, and as a core component of project costs, materials and equipment management must continuously improve its system platforms, deepen refined management practices, and further strengthen standardized operations.To solidify the foundation of management, Li Huitao focused on promoting three key management systems: the Internal Accounting Management System for Modular Joint Construction Projects, the Management System for Machinery and Equipment Leasing Settlements, and the Management System for Reusable Tools Leasing Settlements. He stressed that all personnel must strictly comply with these systems, ensuring their effective implementation to drive precise cost control across projects.Subsequently, Song Mengfei and Yao Zhihong from the Materials and Equipment Management and Procurement Center, together with Yang Tongxiang, Materials Supervisor of the Fuxian Power Plant Project, conducted hands-on training sessions using the Glodon system. They presented practical procurement case studies and shared effective inventory management techniques, helping participants enhance their professional skills and operational capabilities.Expert Training Drives Digital TransformationGlodon consultant Du Haoxian delivered a lecture on the theme of the "Intelligent Weighing System." Aligning with industry trends and the company’s operational needs, he first analyzed the pain points of traditional weighing methods—particularly in data accuracy, supervision, and efficiency—and emphasized that digital transformation is an inevitable path for modern materials management. He highlighted that the intelligent weighing system serves as a core tool for achieving refined material acceptance.Through real-world case demonstrations, Mr. Du explained in detail how the system leverages advanced technologies such as AI-powered license plate recognition and infrared positioning to enable fully automated, unattended operations throughout the entire weighing process. He underscored the system’s ability to prevent fraudulent practices—such as incomplete vehicle weighing—ensuring data integrity from the source.Mr. Du shared successful pilot outcomes from the Shanggao, Fenyi, and Hami projects, where the system enabled full traceability of material data and effectively supported cost control and quality management. During the interactive session, he answered practical questions from attendees, addressing on-the-ground challenges and laying a solid foundation for broader system adoption across the company.The system conference successfully completed all scheduled agenda items and achieved its intended objectives. The meeting clearly emphasized that all materials and equipment management personnel must fully implement the spirit of the conference by deeply integrating the three core management systems with intelligent management platforms. They are required to strictly adhere to the principles of "standardized management, regulated operations, and traceable processes." By working together, the team aims to elevate the company's materials management to a new level, injecting strong momentum into cost reduction, efficiency enhancement, and high-quality development.Submitted by the Materials and Equipment Management and Procurement Center

On the morning of November 29, 2025, as the early winter sun rose over the Bashu region, the construction site of the SPIC Dazhou Coal-Power Project was already alive with activity. At 7:38 a.m., amid thunderous firecrackers and the deep rumble of large concrete pump trucks, the first batch of concrete was successfully poured into the base slab of the project’s iconic chimney foundation. This milestone marks the official start of main structural construction and represents a significant phase breakthrough for the project.At the construction site, operations proceeded in an orderly and impressive manner. The towering concrete pump boom, like a giant’s arm, hovered precisely above the chimney foundation—densely reinforced with carefully tied steel bars. Under the joint witness of representatives from the owner, EPC contractor, supervising team, and our company, uniformly mixed concrete flowed steadily from the transit mixer trucks, continuously filling the foundation formwork. Construction crews closely monitored every phase of the pour, ensuring accurate placement and proper compaction to guarantee the quality of this "first cubic meter" of concrete. Beaming with excitement and pride, the entire team celebrated this moment—a culmination of days of meticulous preparation and tireless round-the-clock efforts now transformed into shared joy and accomplishment.As one of the key structures in a power plant, the quality of the chimney’s mass concrete foundation directly impacts the long-term safety, stability, and durability of the entire structure. The successful completion of this pour not only establishes a solid foundation for the upcoming construction of the hundreds-of-meters-tall chimney shaft but also significantly boosts team morale, injecting strong momentum into the full-scale advancement of subsequent project activities.Achieving this critical milestone would not have been possible without the strong support and sound decisions from leaders at all levels, as well as the close collaboration and dedicated efforts of all functional departments. From initial planning and administrative approvals to technical reviews and resource coordination, the entire organization has worked together with unity and determination, removing obstacles and providing solid backing for project progress.The success of the first concrete pour marks both the culmination of a phase and the launch of an intensified push forward. Seizing this moment, the Dazhou Coal-Power Project team will uphold the principle of "safety first, quality paramount, continuous improvement," carry forward the spirit of hard work, organize scientifically, construct meticulously, and strive to meet every upcoming milestone—ensuring the project is completed on time, efficiently, and to the highest standards, contributing once again to the company’s high-quality development.Submitted by: Sichuan Dazhou Coal-Power Project Department

At 15:58 on November 25, 2025, accompanied by joyful firecrackers, the parapet wall pouring of Row A in the main powerhouse of Unit 4—the project constructed by our company for the Shaanxi Yulneng Hengshan Power Plant Phase II 2×1000MW Units Project—was successfully completed. This marks the smooth topping-out of the main structural work of Row A in the main powerhouse of Unit 4, signifying a phased victory in the project’s construction and laying a solid foundation for subsequent works.Since the project’s commencement, the project team has firmly focused on the goal of building a "model-quality project," efficiently coordinating labor allocation and process sequencing, strictly implementing the management philosophy of "advance planning and model-guided execution," and comprehensively promoting the company's standardized construction techniques. Thanks to standardized site management and high-quality construction results, the project has earned joint recognition and high praise from the EPC contractor, supervisory unit, and owner.Going forward, the project team will continue to uphold the corporate spirit of "unity and dedication, innovation and excellence, perseverance, and steady progress," adhere to the core principles of "safety first, quality paramount," implement meticulous management throughout the entire construction process, strengthen control over details, emphasize execution and accountability, and spare no effort to advance the follow-up construction. We are committed to ensuring the project is successfully completed to the highest standards and with outstanding quality.Submitted by the Project Department of Yulneng Hengshan Power Plant Phase II