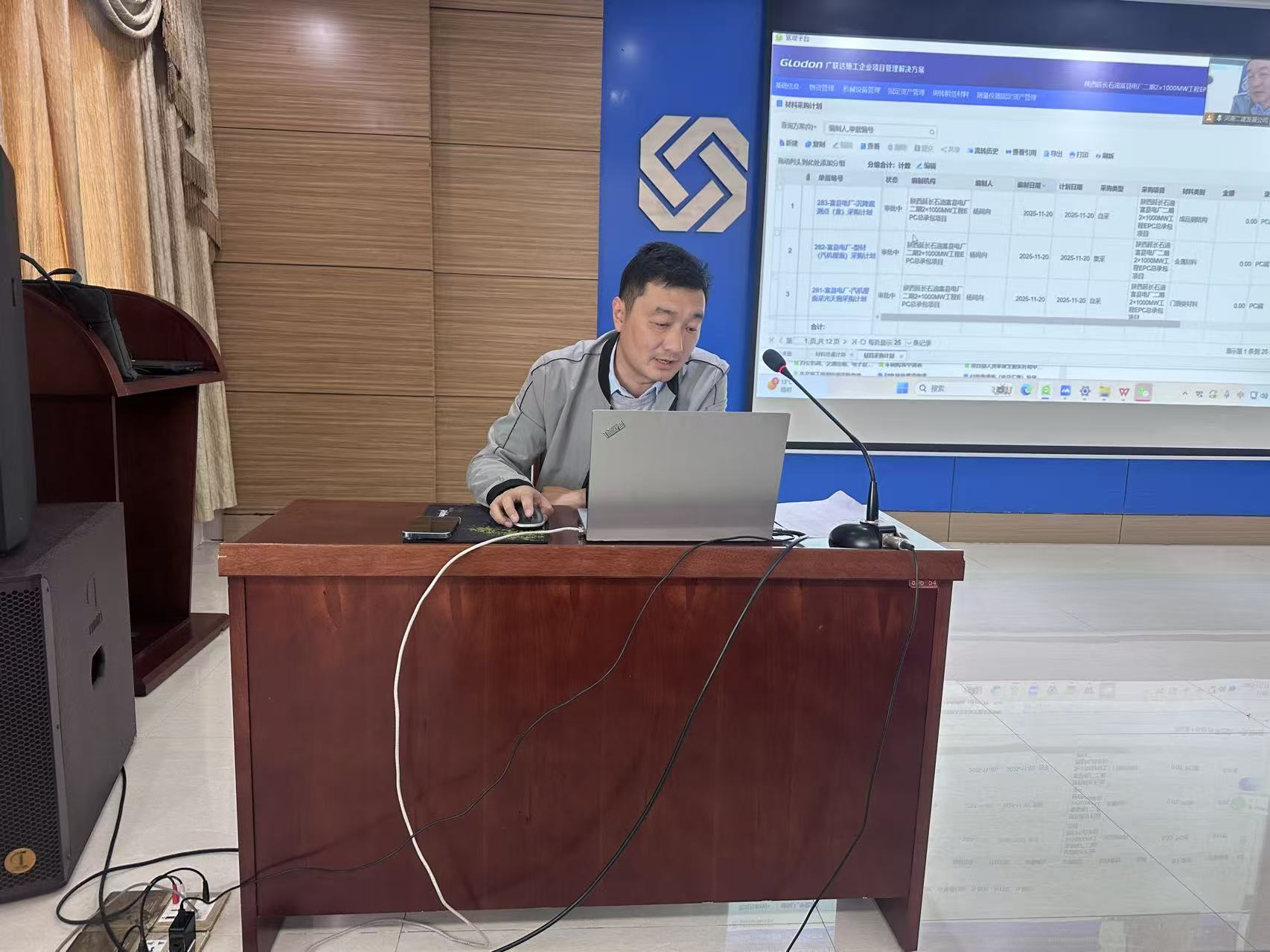

The Materials and Equipment Management and Procurement System Conference was successfully held on November 21, 2025, with the aim of further improving the company's materials and equipment management, standardizing management processes, and achieving the core objectives of enhancing quality and efficiency while reducing costs. Over 40 project-level materials and equipment management personnel attended the meeting through both online and offline formats. System Training Strengthens Management Foundation In his opening remarks, Li Huitao, Director of the Materials and Equipment Center, expressed sincere appreciation for the hard work and dedication of all materials management staff. He emphasized that the company is currently in a period of rapid development, and as a core component of project costs, materials and equipment management must continuously improve its system platforms, deepen refined management practices, and further strengthen standardized operations. To solidify the foundation of management, Li Huitao focused on promoting three key management systems: the Internal Accounting Management System for Modular Joint Construction Projects, the Management System for Machinery and Equipment Leasing Settlements, and the Management System for Reusable Tools Leasing Settlements. He stressed that all personnel must strictly comply with these systems, ensuring their effective implementation to drive precise cost control across projects. Subsequently, Song Mengfei and Yao Zhihong from the Materials and Equipment Management and Procurement Center, together with Yang Tongxiang, Materials Supervisor of the Fuxian Power Plant Project, conducted hands-on training sessions using the Glodon system. They presented practical procurement case studies and shared effective inventory management techniques, helping participants enhance their professional skills and operational capabilities. Expert Training Drives Digital Transformation Glodon consultant Du Haoxian delivered a lecture on the theme of the "Intelligent Weighing System." Aligning with industry trends and the company’s operational needs, he first analyzed the pain points of traditional weighing methods—particularly in data accuracy, supervision, and efficiency—and emphasized that digital transformation is an inevitable path for modern materials management. He highlighted that the intelligent weighing system serves as a core tool for achieving refined material acceptance. Through real-world case demonstrations, Mr. Du explained in detail how the system leverages advanced technologies such as AI-powered license plate recognition and infrared positioning to enable fully automated, unattended operations throughout the entire weighing process. He underscored the system’s ability to prevent fraudulent practices—such as incomplete vehicle weighing—ensuring data integrity from the source. Mr. Du shared successful pilot outcomes from the Shanggao, Fenyi, and Hami projects, where the system enabled full traceability of material data and effectively supported cost control and quality management. During the interactive session, he answered practical questions from attendees, addressing on-the-ground challenges and laying a solid foundation for broader system adoption across the company. The system conference successfully completed all scheduled agenda items and achieved its intended objectives. The meeting clearly emphasized that all materials and equipment management personnel must fully implement the spirit of the conference by deeply integrating the three core management systems with intelligent management platforms. They are required to strictly adhere to the principles of "standardized management, regulated operations, and traceable processes." By working together, the team aims to elevate the company's materials management to a new level, injecting strong momentum into cost reduction, efficiency enhancement, and high-quality development. Submitted by the Materials and Equipment Management and Procurement Center