Time to wait, good comes. Our company undertake the construction of the country Yuecheng • Rongfu No. 1 courtyard project, after a thousand days of polished and craft, live up to expectations, on October 19 to October 23 ushered in a grand delivery.From a blueprint to quality delivery, from reinforced concrete to buildings.Under the strong support and help of the company's leadership, the project team during the construction period of careful planning, scientific organization, overcome difficulties, fully carry forward the "unity and struggle, innovation and beyond, strong interest, steady and enterprising" spirit of enterprise, after more than a thousand days and nights to stick to, at this moment to exquisite delivery.

At 14:27 on October 13, with a loud "lifting" order at the hoisting site, the machine roared and fireworks played together. The first section of the #F06 wind power unit weighing 60.63 tons of concrete tower was completed by the large crane and ground staff to complete the positioning and fixing, and the base was seamlessly "docked", which marked the official entry of the Yuanyang Runyuan 100MW wind power project into the hoisting construction stage. Ren Hao, engineering director of Beijing Tianrun New Energy Investment Co., Ltd. East China, Li Hongxing, general manager of our company, and the project management team witnessed this exciting moment.The project is located in Yuanyang County, Xinxiang City, Henan Province, the eastern part of the county, Taiping Township, Dabin Township, Doumen Township, a total of 16 GW191-6.25MW wind power units are constructed. The foundation adopts the form of cast-in-place pile and cavity circular extended bearing platform, and the fan adopts the form of mixed tower, consisting of 31 sections of concrete tower, 1 section of conversion section and 2 sections of steel tower.In order to ensure the safe and orderly development of the fan hoisting work, the project department has organized the supervision, tower manufacturers and hoisting units to carry out the work sorting meeting before hoisting for many times. For the core and key links of large cargo transportation and hoisting construction, detailed planning, demonstration, field investigation and test have been carried out, and the tower manufacturers have organized detailed safety technical disclosure to all the personnel involved in hoisting operation.All the staff of the project department actively practice the safety concept of "safety management, everyone is responsible", and earnestly implement the policy of "enhancing quality awareness and promoting high-quality development";in strict accordance with the requirements of the company, careful deployment and refined decomposition of each link of hoisting operation, formulate construction safety plans, emergency plans and hoisting operation plans.The construction teams work together and cooperate with each other to do a good job in the field work of crane and other equipment and facilities, ensuring the smooth completion of the fan tower hoisting task.Next, the project construction team will unite as one, make persistent efforts, orderly promote the construction, complete the construction task with quality and quantity guarantee, and steadily move towards the goal of grid connection as scheduled!

On September 29, 2023, on the day of the Mid-Autumn Festival, with the first fan impeller accurately docking with the engine room at an altitude of 110 meters, the first fan lifting of the wind power project in Yutang Township, Wanshan District, Guizhou was successfully completed. In the process of lifting work, the project team of Yutang Township, Wanshan District attached great importance to careful planning, overcame all kinds of difficulties, gave full play to the role of the project department in overall planning, cohesion and linkage, and made concerted efforts to solve the problems in the lifting process of the project. Combined with the specific situation of the construction site, the construction period was reasonably arranged, the construction was scientifically organized, and the lifting task was safely and orderly promoted.The successful lifting of the first fan marks the phased victory of the wind power project in Yutang Township, Wanshan District, Guizhou, and has accumulated valuable experience for the subsequent lifting of mountain wind power fans.Next, the project team of Yutang Township, Wanshan District will strengthen the construction management under the premise of strictly ensuring safety and quality, pay close attention to the time node of the project, accelerate the construction progress of the project, and ensure the full capacity grid connection of the project as soon as possible.

On the eve of the National Day and the Mid-Autumn Festival, in order to further enrich the spiritual and cultural life of the staff and improve their safety awareness, on September 27, the organs organized the "celebrate the Mid-Autumn Festival • celebrate the National Day" collective movie watching activity, more than 50 employees participated in the movie watching activity.The film "All or Nothing" to watch the anti-fraud propaganda introduced, focusing on the current repeatedly prohibited network fraud, online gambling traps, recruitment abduction and other real fraud cases, revealing the terrible insides of the whole industry chain of overseas fraud, and fully restoring the "fraud group" crime and terrorist means.Through the movie plot, revealing the dark and cruel behind the fraud, so that more people can understand the fraud routine, to avoid falling into the traps of the fraud group, has a strong educational and practical significance.After the movie watching activity, everyone responded strongly, and said that they would share the anti-fraud knowledge with their relatives and friends around them, remind them to increase their vigilance to unknown links, strange calls, high-paying recruitment, online games and other content, further promote the anti-fraud education and publicity, and deeply realize that "pie does not fall from the sky", there is no such achievement, only down-to-earth efforts and sober self-discipline can lead to a broader life.

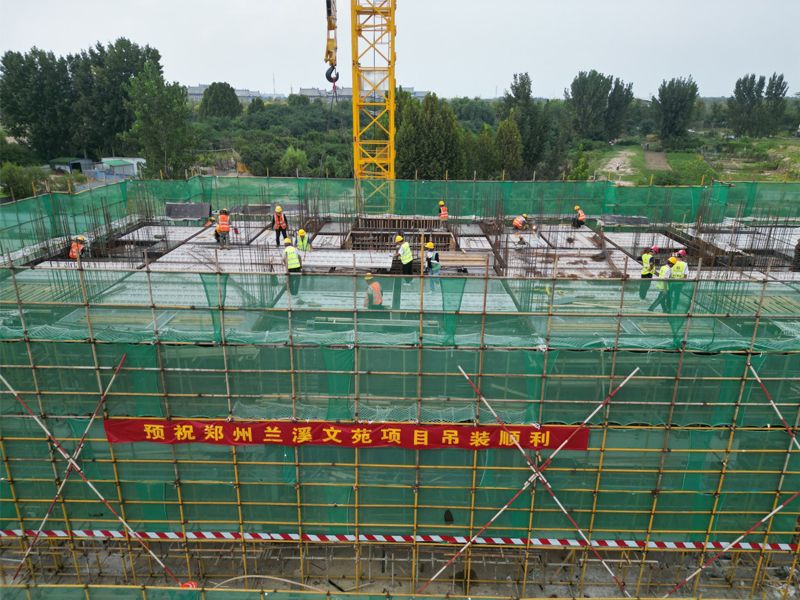

In order to promote the high-quality development of prefabricated building, improve the ability of prefabricated workers, and promote the industrialization, greenization and intelligent development of building.On September 25, 2023, the prefabricated building observation activity of Zhengdong New Area was successfully held in Lanxi Wenyuan Project.The observation activity was hosted by Zhengzhou Engineering Quality Supervision Station, undertaken by Henan Zhengxin Kechuang Co., Ltd. and our company, Zhengxin Kechuang Engineering Platform, Lanxi Wenyuan Project, Vanke Simiyuan Project, China Resources Runju Project, Henan Lvzhu Prefabricated Building Materials Co., Ltd. and other units' relevant leaders and representatives attended the event.At the observation meeting, the relevant leaders of the quality supervision station made an opening speech, and expressed their affirmation of the regular management and construction achievements of Lanxi Wenyuan Project since its entry.It is emphasized that the decisions and deployment of the CPC Central Committee and the State Council on vigorously developing prefabricated green buildings should be implemented, and efforts should be made to promote the high-quality development of prefabricated building in Zhengdong New Area, improve the ability of prefabricated building workers, and promote the industrialization, greenization and intelligent development of building.This observation combined with the characteristics of project quality management set up two exhibition areas: process method model and real building working surface model. The project through the setting of physical model, real building samples, arrange staff on-site explanation and other ways, the project in the implementation of construction quality management standardization to carry out a comprehensive display.The main content of the exchange is: prefabricated component transportation, field acceptance, hoisting and installation, vertical component sleeve grouting, laminated plate water and electricity installation, concealed process acceptance and other key construction methods and construction processes to explain and display.Project management personnel, supervision units, the owner unit also made a detailed introduction to the observation group from the aspects of construction quality control, quality supervision, project progress and so on.On the site, the spectators have observed and exchanged the project prefabricated buildings, as well as the quality sample exhibition area, prefabricated building exhibition area and construction site.The observation group gave affirmation to the project quality management, emphasizing that all units should learn the quality observation experience in depth, strengthen the quality benchmark and align the consciousness, strictly implement the requirements of "Quality Month", strengthen the quality supervision, strengthen the study and exchange, create a good atmosphere of everyone attaching importance to quality, everyone focusing on quality, everyone promoting quality, everyone participating in quality, enhance the quality competitiveness in construction engineering, and build a quality project.During the observation, participants also discussed and exchanged in depth on the topics of quality control, safety management, green construction, etc. The observation meeting ended successfully on the afternoon of September 25.Project Overview:Lanxi Wenyuan Project is located in Zhengdong New Area, Zhengzhou City, Henan Province, west of Xianchuan Street, north of Yaoqiao Road, east of Xingjian Street, with a total construction area of 138,000 m2 and a contract amount of 610 million yuan.The project is composed of 10 high-rise buildings, 1 multi-storey building, and one and two underground garages, among which 4#, 5#, 9# and 10# floors are prefabricated buildings, with an assembly rate of 51%.The assembly components use prefabricated sandwich external wall, prefabricated shear wall internal wall, prefabricated staircase, stacked plate, internal partition wall ALC board, etc.

The autumn wind brings good news, and the fruits are abundant. At 17:07 on September 27, Tianrun Wuyang Runjin Wushui 50MW Wind Power Project successfully sends power. The realization of this important node goal marks that the boost station has the conditions to ensure the reliable operation of the factory load, and lays a solid foundation for the whole set of unit start-up. Tianrun Wuyang Runjin Wushui 50MW Wind Power Project has an installed capacity of 50MW, and the boost station expands a 50MVA voltage regulating and boosting transformer, a set of 35KV power distribution device, a set of +13MvarSVG dynamic reactive power compensation device, a set of 5MW/10MW energy storage device and a set of grounding and station use transformer. After the main transformer is boosted, the original 110KV outgoing line is used to access the 110KV Macun transformer of the national network. Equipment manufacturers, commissioning units and installation units cooperate closely, and the on-site operators operate, inspect, record and accept in strict accordance with the factory power operation procedures, and successfully complete the work tasks of the backward power transmission. All the staff of the project department focus on the time node, accelerate the promotion, press and consolidate the responsibilities of all parties, strictly ensure the safety, quality and progress of the project construction, and fully promote the high standard construction, high efficiency and high quality completion of the project.

July 16, with the completion of the final concrete pouring, Guoyuecheng Yufu project phase II 13#, 15#, 21#, 22# building completed the second phase of the pre-sale node target 3 days in advance, won the praise of party A and supervision, and won the honorary certificate of "excellent project department" of party A, the site production manager Fan Yongpeng won the honorary certificate of "advanced individual".Guoyuecheng Yufu phase II as the company and another city real estate cooperation of the third civil construction project, Yufu phase II since the beginning of the project has been continued the company's high standards, high quality, high efficiency style of project planning and management, the project team in the face of hot weather, flood disasters and government dual control and many other challenges, the project department through careful organization, day and night, actively promote the company's standardized process construction, continue to improve the company's civil construction standards. With the completion of the second phase of pre-sale node, the project has fully entered the main construction stage. In the subsequent construction process, all the staff and labor team of the project department will continue to carry forward the enterprise spirit of "unity and struggle, innovation and transcendence, strong and profitless, steady and enterprising", and in line with the principle of "safety first, quality first", always unite together, orderly response to multiple tests such as environmental protection, drainage, high temperature, etc., to ensure the safe and orderly development of the project construction.

At 8:20 am on September 9, with the order of "lifting", a "parts" weighing several tons rose slowly with the help of the crane arm, fell steadily on the joint surface, and was docked seamlessly. The first lifting of the prefabricated PC components of the Lanxi Wenyuan project undertaken by our company was successfully completed, which opened a new chapter in the construction technology of our company's prefabricated housing.Lanxi Wenyuan project has a total of 10 buildings, among which 4#, 5#, 10# main building 2, 3, 4 layer horizontal structure for prefabricated prefabricated components, vertical structure for cast-in-place concrete, 5 layer and above for full prefabricated structure, 9# building 6 layer and above for full prefabricated structure.The lifting is the lifting of the 2 layer stacked plate of 10# building. This time, the stacked plate produced by Henan Lvzhu prefabricated building materials is adopted. Through precise calculation and scientific and reasonable construction and prefabrication, the construction efficiency can be maximized. After the prefabricated components are transported to the construction site and installed, the cast-in-place concrete components and PC components will be poured and connected to ensure the safety of the house quality and improve the overall safety level of the residence.the 2 layer stacked plate of 10# buildingThe smooth hoisting of PC components in Lanxi Wenyuan Project marks the substantial progress in the application of prefabricated housing of our company. Our project department will continue to strictly abide by technical regulations, strengthen supervision and management, pay close attention to project quality, ensure safe construction, and accumulate construction experience for the development of prefabricated buildings of our company.

At 17:04 on September 7, 2023, the hoisting of the first wind turbine of the 50MW wind power project of Tianrun Wuyang Runjin Wushui was successfully completed, realizing the goal of "approval, commencement and first hoisting in the same year", and starting the first gun of the hoisting of Tianrun Wuyang Runjin Wushui project.Before the hoisting operation, in order to ensure the safe, orderly and efficient lifting work, the project department actively coordinated the road transformation and transportation of large equipment to the site, organized the supervision and hoisting personnel to seriously discuss the operation plan, strictly conducted the safety technology disclosure, clarified the operation responsibilities, carefully analyzed the operation risks, formulated preventive measures, and made detailed and solid preparations for the hoisting operation.In the hoisting operation, the safety upgrade control measures were adopted. In the hoisting process, the owner's leaders and the project manager Qin Zhao stood by the whole process to supervise, to ensure the safe and smooth completion of the hoisting operation.The successful completion of the hoisting of the first fan marks a key step in the construction of Tianrun Wuyang Runjin Wushui wind power project. Next, the project team will continue to give full play to its hardworking style, grasp the promotion with the momentum of take-off, grasp the implementation with the speed of running, control the construction safety, process and quality with high standards and strict requirements, and strive to achieve the goal of full-capacity grid-connected power generation in 2023.

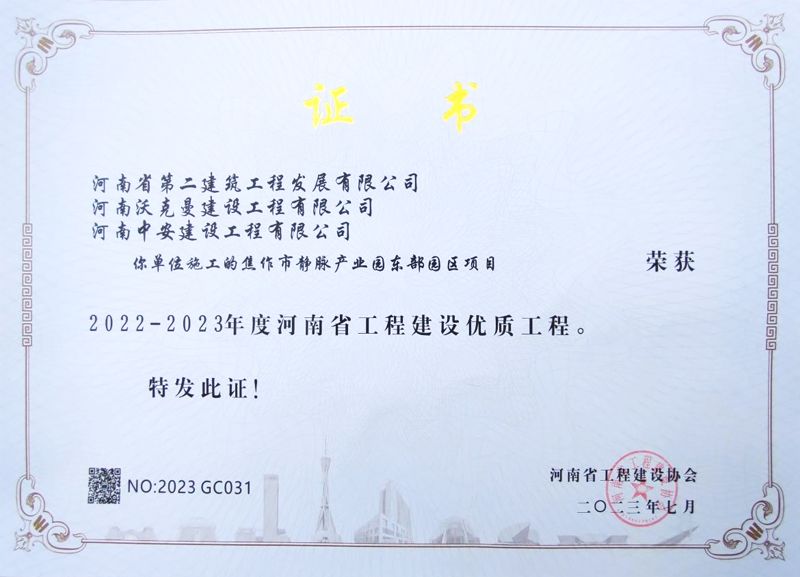

Recently, Jiaozuo East Garbage Incineration Power Generation Project, which was undertaken by our company, won the 2022-2023 High-quality Engineering Construction Award of Henan Province. Since the establishment of Jiaozuo East Garbage Incineration Power Generation Project, we have established the quality goal of high-quality engineering, and under the strong support of the company's leaders, the project manager Yang Dejun led the project team to improve the construction quality from multiple aspects.From the planning and preparation of the project, the optimization of the construction plan, to the construction quality control and the collation of the internal industry data, we have strictly controlled the construction quality, strictly implemented the company's quality management system and acceptance process, comprehensively prepared the technical data, firmly grasped the structural quality, and always promoted the project construction with high standards and strict requirements. The award of the 2022-2023 High-quality Engineering Construction of Henan Province is the high recognition of the construction quality of our project by the Henan Engineering Construction Association and the Xiuwu County Engineering Quality Supervision Station and other departments, as well as the recognition of our company's management level and ability, and the verification of our company's excellent reputation in the engineering field. We will take this as an opportunity to strengthen our confidence, continue to work hard, and constantly improve our engineering quality and management level. Jiaozuo East Garbage Incineration Power Generation Project will continue to uphold the concept of high quality and efficient construction, provide customers with better engineering services, and make greater contributions to society.